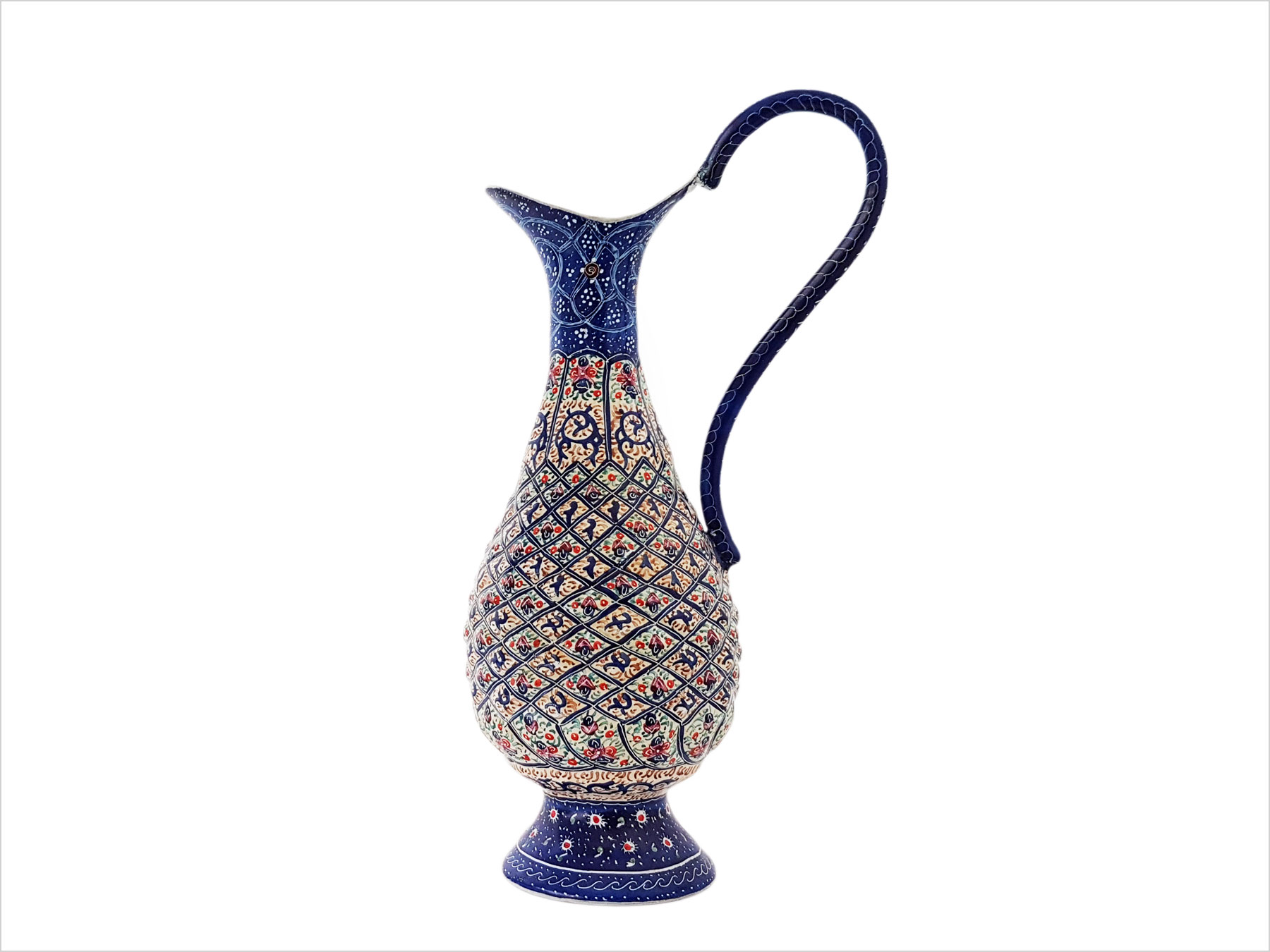

Enameled copper pitcher-1001

Ismaili enameled copper pitcher is 16 cm in size. This product is the work of Isfahan artists. And beautifies your home and decor.

enamel-work

enamel-work art is one of the branches of handicrafts. This art is often done on metals such as copper, as well as gold and silver. This art is very beautiful and eye-catching 5000 years old. Experts have studied history and have come to the conclusion that art dates back to the Achaemenid period. This art is done in most parts of Iran, but it is mostly done in Isfahan and there are famous masters in this city. The background color of the enamel is often blue, and for this reason the word enamel is used to remind us of the sky. But along with blue, other colors such as green and red are also used. The background is drawn with a white pen.

enamel-work methods

Cellularenamel: It is an old method in which the metal wire is soldered and the enamel paint is poured on it and covered with colorless glaze. Enamel painting: It is a method that is used to produce and make an enameled dish. After preparing the dish, it is glazed 3 times and goes into the oven, and at the end, after the glaze is fixed on the dish, painting is done. . Inlaid enamel:In inlaid enamel, ruby-shaped beads are placed on the design. These beads are made of colored glass. This type is also not done now. Embossed enamel: This art is a mixture of engraving and enameling. Because it is embossed with the art of embossed master and enamel work is placed on it, it is called by this name.Lattice enamel:It is one of the most delicate types of this art and it can be said that gold and silver enameling is done with this method. Sugar enamel: This type of enamel is very similar to painting enamel, but the difference is that in this method, colored glaze is used.

Moore tools needed for enameling

- Brush

- Copy pencil

- closed

- Infrastructure

- enamel

- Color

- Enamel furnace and its tools

Enamelling method

1. Provision of infrastructure

In the first place, enamel making gold must be prepared, which is done in the following two ways:

- Bending method

- Hammering method

.

2. Cleaning the infrastructure

Our prepared metal surface should be very clean so that no fingerprints should be on it. The following methods are used to clean the work surface:

- Wash with nectar and vinegar

- Sulfur ink (sulfuric acid)

- Soap, metal fibers, sandpaper and salt water

3- Glaze preparation

It is a necessary material for glaze engraving. In order for the material to have sufficient and desired adhesion, they are used with the grain.

4- Glazing

The next important step is glazing, which can be done in the following two ways:

- Spray method by pistol

- Manual method or immersion

After finishing the work, our glazed container should be dusted.

5. Bake the glaze

When the glaze is completely dry and free of dust, it should be baked in an oven. The required temperature for baking is 900 degrees Celsius and the time is 2 to 3 minutes.

6- Paint preparation

For painting on enamel, paints that are metal oxide powder and refractory are used.

7. Transfer the design to the glaze

At this stage, the desired role, which is mostly Islamic and chicken and hunting grounds, is transferred to the container.

8. Painting

After transferring the design to the painting container, the design begins with engraving.

9-Baking paintings

After painting, the dish is placed in the oven. At a temperature of 600 to 750 ° C.

10-Completion of work

Finally, brass or silver gutters are used to clean the edges of plates and dishes.

Golden Mart business group is a supplier of various Iranian and foreign products and is always at the service of our dear customers.

Reviews

There are no reviews yet.